Making the Grade: How Cigars are Tested

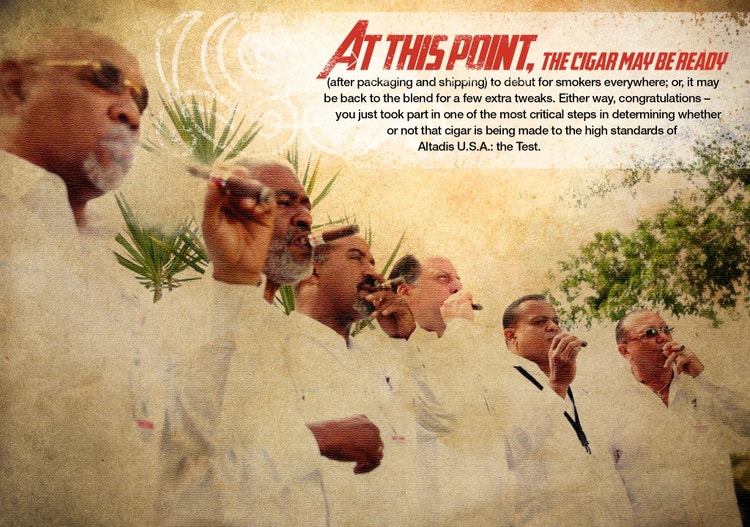

In the long process of making premium cigars, one of the most important steps is the testing and tasting of the tobacco. At Tabacalera de Garcia, located in La Romana, Dominican Republic, factory tastings are conducted to ensure that the cigars meet certain standards of draw, combustion, taste, aroma and body. This quality control also ensures that the production team is on the right track with both new and old blends from among the biggest names in cigars, like Romeo Y Julieta, H. Upmann and more. While almost every cigar factory engages in this practice, how cigars are tested at Tabacalera de Garcia is a bit of a different animal. Here, the testing includes the Grupo de Maestros – a renowned group of cigar experts – as well as another 50 people, selected from every team that works in the factory. This wide variety of viewpoints and tastes will work together to guarantee an outstanding smoke with every cigar.

Blending A New Cigar

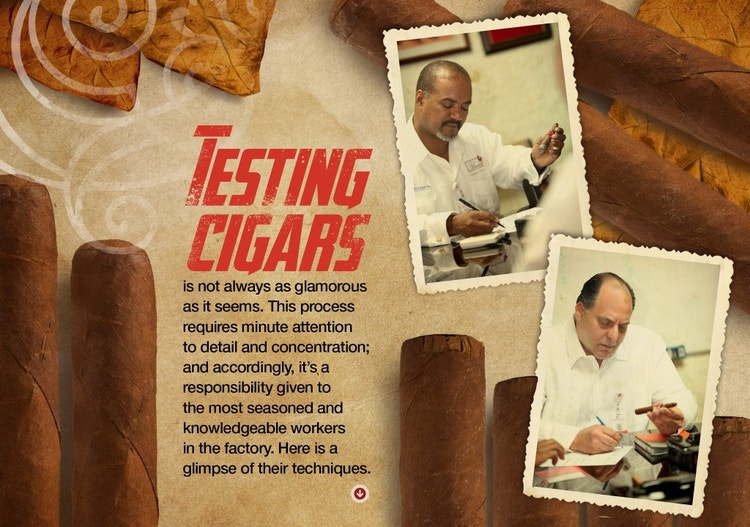

The tastings occur in a big and well-lit room in the factory. The factory’s testers take their seats along with the Grupo de Maestros, who are all ready to taste the blend. Once everyone is seated, a tray with unbanded cigars is passed around. Each individual takes and observes an unlit cigar. Smelling, taking cold draws and feeling the cigar’s wrapper is commonplace. From there, the different rituals of cutting and lighting the cigar begin. Some use punch cutters, others guillotine; cedar splints and cigar lighters are used to light up. A buzz of excitement takes over the room as the testing begins.

Each tester has a sheet in front of him or her, like this, on which they make notes. This page acts as each person’s journal, used to describe the cigar they taste. They’ll observe and describe characteristics of the cigar, such as construction; they grade whether it’s firmly wrapped (but not too tight), while noting the airflow of the cigar and the amount of smoke produced. The construction of the ash is important, too…testers are looking at the color (grey or white, based on the tobacco’s country of origin and the nutrients in the soil), how compact the ash is and when it breaks off – which, if all goes well, is an ash of at least an inch. A cone-shaped ash is a tell-tale sign that a cigar was rolled with the book binding technique and that the cigar has bolder, less combustible tobaccos in the center.

We, as cigar enthusiasts, generally accept the notion that each person’s palate is different. But for the purposes of the test, taste is one of the most important observations when sampling premium cigars. The tester writes down the notes and aromas they detect throughout the experience. They are also asked to sketch the shape of their cigar throughout the smoke to ensure uniformity. Testers are constantly asking themselves questions about the type of flavors they detect, what kind of smoke they are experiencing and how the cigar feels to them. This allows them to express, in detail, their observations. Once the sampling is complete, the notes are collected and analyzed – and depending on what the cigar makers learn from the results, they’re informed on where to take their blend next.